1. Connect

In the simplest case, KIS.ME only needs a power connection and WLAN. This makes the installation process quite simple.

Simply digitalise and optimise wherever people work - even at remote production sites or manual workplaces. In the blink of an eye, you can make your company more transparent by networking manual processes, for example. Optimisation has never been so easy - without additional programming or management consultancy. Connect, set up and get started. Just try.

In the simplest case, KIS.ME only needs a power connection and WLAN. This makes the installation process quite simple.

KIS.ME must be set up once. To do this, the KIS.ME devices must be added to the KIS.MANAGER account and the WLAN network and you are ready to go.

Once set up, data points and information are collected directly during running processes. From this data, everyone can then identify optimisation opportunities themselves and streamline the processes.

Because automation and digitalisation often have a complex effect, we have bundled our competences in electromechanics, electronics and software. To provide you with a product with which you can optimise your production conveniently and flexibly: KIS.ME. This includes the KIS.LIGHT signal lamp, the KIS.BOX push-button box and the KIS.MANAGER web portal - for configuration and evaluation.

Modern machines and systems constantly collect data, some of which is evaluated directly. But almost every machine and plant manufacturer has its own system. Maintaining an overview here is often a challenge. In contrast, manual processes are usually not networked at all and without collected data it is difficult to even identify optimisation potential.

The KIS.LIGHT is a signal light that can light up and flash in RGB colours. It can thus visually indicate various states. In the most common case, it can replace a conventional machine light and at the same time transmit the machine's status to the KIS.MANAGER.

The KIS.BOX has two pushbuttons, each of which can be illuminated with different RGB colors. These pushbuttons detect human inputs and transfer them to the KIS.MANAGER. The KIS.BOX can be used to acquire external signals or to control other machines and systems.

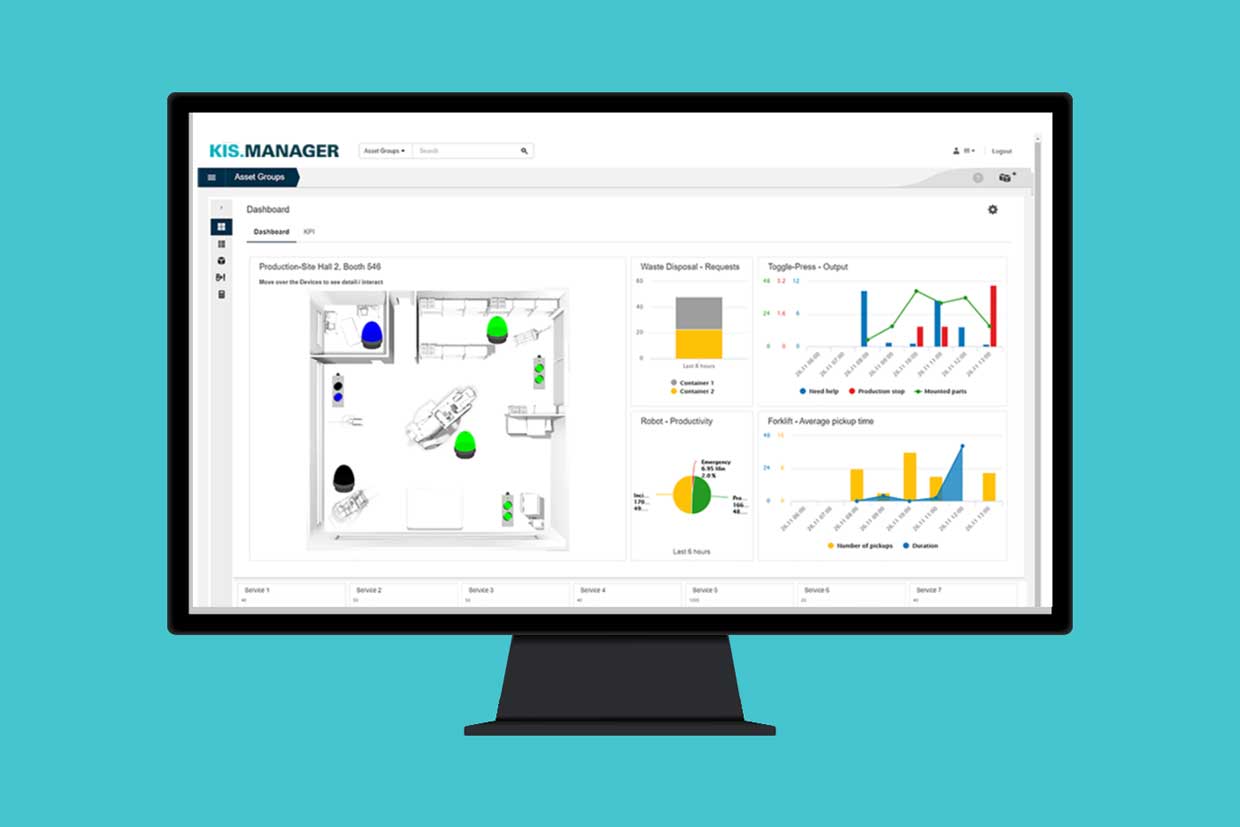

The KIS.MANAGER is the heart of KIS.ME. All devices can be managed and controlled with the KIS.MANAGER. Simple rules can be used to generate automated sequences and thus optimize processes. With the help of digital store floor plans, one keeps track of one's own machines and equipment at all times.

KIS.ME provides a solution: increased transparency - interaction in the actual control of the processes. This does not require a certain company size or a special industry. Whether manual workplaces, intralogistics or material supply; whether crafts, industry or municipalities - there is potential everywhere. You can implement downstream optimisations on your own and save time and money in the process.

With KIS.ME you define and determine your own key figures, digitalise existing machines or monitor your processes in real time - without any programming or external consultants. Finally, you get relevant data where you have always been looking for it and digitalisation of manual workplaces with a focus on transparency, effectiveness and sustainability.

KIS.ME can be used very individually and is therefore very versatile. In the first step, however, we designed KIS.ME for industrial use - everywhere where production takes place and people work. We defined three main areas of application:

The following videos illustrate the application possibilities of KIS.ME in these three areas.

Wherever production takes place, there must also be a flow of goods. Auxiliary materials and raw materials have to be brought to the production site, and finished goods or waste materials have to be transported away. With KIS.ME, this transport of goods can be controlled in a very simple way and also optimised and streamlined.

Nowadays, many machines and plants are already intelligently networked and provide the desired data for optimisation. But there is still a lot of manual work that is done by people. And what about digitalisation there? KIS.ME intervenes here and simply digitises these manual processes and manual workplaces in order to uncover the potential for optimisation here as well.

Many machines and plants have been successfully and productively in use for several years. No one thinks of replacing them, as they usually work perfectly. But what if one day they stop working? Are these machines already so modern that they automatically sound an alarm and inform the responsible machine operator? Do these machines provide the desired information on productivity and other key figures?

With KIS.ME, existing plants and machines can be digitalised in the simplest way. Retrofit made easy!

Contact us if you have any questions, want to test KIS.ME free of charge or want to get started directly with KIS.ME. Fill out this form or contact your personal sales representative in your region directly.

Attention: KIS.ME is currently sold exclusively to our customers in Germany, Austria and Switzerland.