Individual

Optimal workplace solutions for assembly, packaging or control activities with endless adaptation possibilities (dimensions, panels, ESD, material supply, etc.)

Modular pipe systems

Attachments

Workplace systems form the basis for the vast majority of assembly for industrial use, packaging and testing activities in production. Industrial workstations can stand alone or combine entire processes and successive processing steps in the form of an assembly line.

By combining them with flow racks and provision racks, workplace systems made of pipe racking system provide the perfect workspace and ensure that there is no waiting time during assembly.

Different versions as sitting, standing or sitting/standing workstations:

Thanks to our modular systems, it is possible to design ergonomic workstations, workbenches and working environments completely individually. Whether seated, standing or sit/stand workstations - you can increase the productivity of your company and implement the latest trends in lean production, while at the same time protecting the health of your employees.

The industrial workplace must adapt to the person, not the other way round. Aspects such as optimising individual gripping paths, height adjustability, or the right lighting for different activities (e.g. checking and testing) play an important role.

Optimal workplace solutions for assembly, packaging or control activities with endless adaptation possibilities (dimensions, panels, ESD, material supply, etc.)

Height-adjustable industrial workstations, suitable lighting and, for example, swivel arms for the physical relief and increase in performance of the employees.

Increase output by adapting the industrial workstations to the individual work steps and processes.

You want to know more? We will be happy to advise you.

The BeeWaTec bestseller (dimensions: 800x1074x2200 mm) with a table height of 900 mm allows a load of up to 200 kg (with evenly distributed load).

Alternatively, the basic element is available with different table tops, in different tube colours as well as an ESD version.

The BeeWaTec bestseller with a table height of 900 mm allows a load of up to 200 kg (with evenly distributed load). Additional accessories increase the ergonomics at the workplace:

The basis of ergonomic workplace systems, industrial workstations and workbenches are our strong pipe racking and square systems. These offer high stability and high load-bearing / heavy duty capacity, despite extraordinary flexibility. In combination with our wide range of panels, LED lighting and powerful lifting technology, you can realise an optimal working environment.

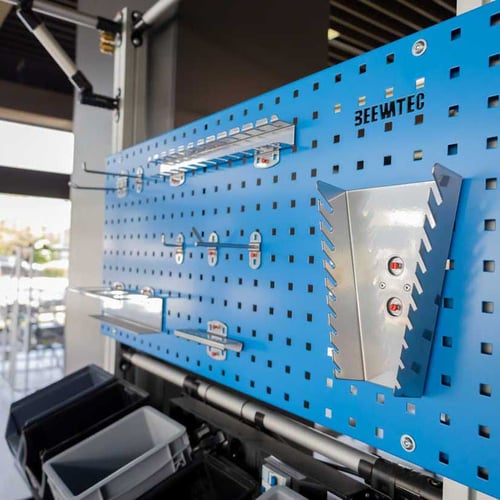

When additional accessories are used, our industrial workstations offer a whole new experience. Perforated panels and whiteboards help with tool provision and planning. Magnetic boards, swivelling shelves or monitor holders ensure the provision of information such as work or test instructions. In short: we have the right accessories for every requirement.

All our workplace systems can be realised as ESD versions.

With our 3D software BEEVisio, you can design your individual solution quickly and easily. You have direct access to all the individual components you need for planning.

If required, we can handle the construction work for you. Talk to us and find out more about your options.

Start with BeeWaTec >

By using our lifting technology systems, you get workplaces that are not only ergonomic for the average person, but can be individually adjusted in height by each of your employees. In this way you increase the satisfaction of your employees, their health and at the same time your output.

Contact us for more information >

Combine mobile and flexible racking solutions and infeed sections by docking them from the side, for example, or integrate them directly into your workplace. In this way, you achieve a seamless material supply without additional walking distances.

Contact us for more information >

We offer the right table panel for every application. For example, if you work with sensitive materials in your work environment and want to avoid damage on site, it is advisable to provide the worktop with soft plastic or with rubber.

For other assembly applications, we offer stainless steel-covered work panels.

In addition, we offer special work panels to ensure electrical conductivity for machining and assembling sensitive parts.

Contact us for more information >

The 5S method is an important part of Lean thinking and includes 5 concrete steps to optimise the workplace:

1. Sort

2. Set in order

3. Shine

4. Standardize

5. Sustain

In the field of lean management, the 5S method is seen as a continuous improvement process that helps to reduce waste in the workplace (e.g. by searching for a tool).

The immediate benefits of the 5S method can be produced in most cases without a high capital investment.

However, it is precisely when planning and designing an (assembly) workplace that the "5S" should be taken into account. Perforated boards or whiteboards as the back wall of a workstation help, for example, to sort tools or information and to define storage locations. Drawers or boxes also provide storage space and help to clear the work surface and keep the workplace clean.

Contact us for more information >

Contact us if you have any questions, want to learn more or start your project. Fill out this form or contact your personal sales representative in your region directly.